YPL pressure spray granulator (DF special)

YPL pressure spray granulator (DF special)

Detailed description

overview of equipment

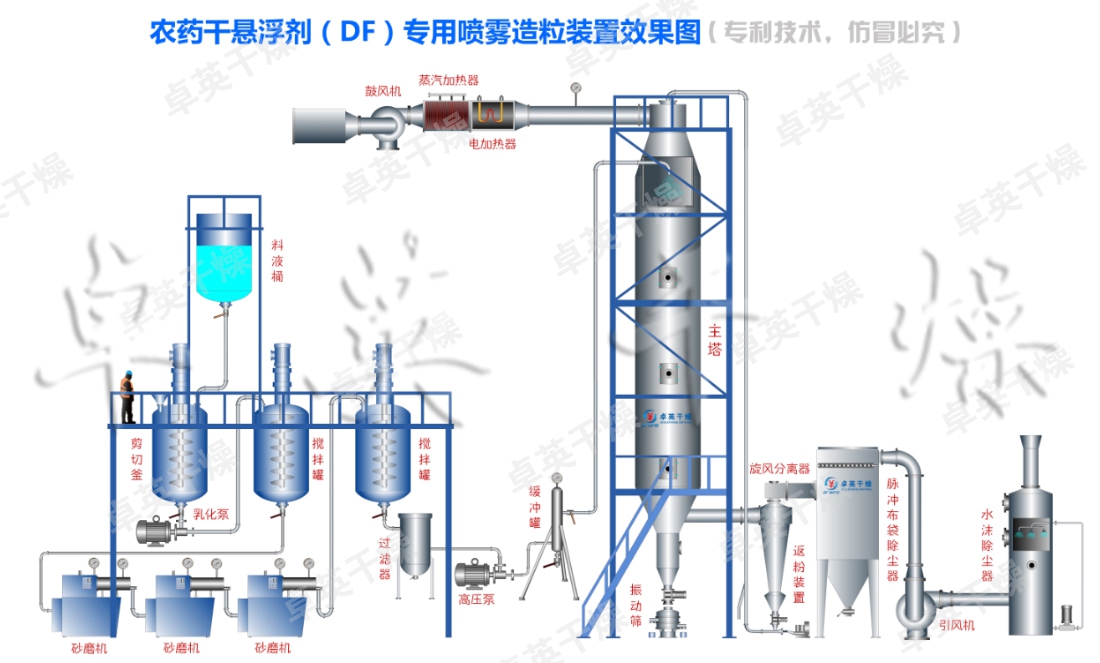

This machine is the production of pesticide spray granulation dry suspension (DF) special equipment, has applied for the national patent, patent No. ZL201120013418.8. spray granulation is the heat suspension with atomizer spray drying chamber to flow, method of evaporate fast drying into fine particles. In a few seconds. To complete the chat also concentrated, dry granulation process. After slurry sand mill after wet grinding is first atomized into droplets of water mist, hot air evaporation, solid droplets within the aggregation of dry particles. The spray granulation made of hollow particles are porous, so in water wetting and disintegration good performance, and high suspension rate, and improve the efficacy, is the representative of green chemical pesticide formulations. At present, the device is in the country has been successful in two Quinclorac, pizotifen benzyl, chlorothalonil, pyrazole azoxystrobin generation Senlian, pyrazole azoxystrobin Ester of acrylic zineb, zinc, Emamectin, mancozeb, nail care, imidacloprid, tribenuron methyl, azoxystrobin, thiamethoxam, Dimethomorph DF in the preparation of industrialization.

the technical advantages of equipment

1., with a built-in whirlwind device (patented technology), the tower bottom feed rate will be increased to the original 60%~70% more than 90%, for the subsequent return of powder provides the possibility

2. a return powder device (patent technology), the fine powder of the cyclone bottom residual fine powder and vibrating screen after the return to the main tower two granulation, which reduces the recovery part of fine powder, but also avoid the energy loss caused by the two drying, but also increase the particle size of the product. Grain rate and recovery rate reached more than 99%, almost no powder processing.

The 3. jet sheet structure is designed by itself, which can be adjusted according to the different material condition and the user's different requirements, so as to achieve the most ideal product effect

4., there are relatively mature dry suspension agent (DF) equipment design, production and commissioning experience, can be organically combined with a variety of different formulations, adjust equipment, to achieve the ideal state

5. fully consider the overall equipment has the advantages of convenient cleaning, a hand hole, without disassembly, convenient for user to replace varieties or production maintenance when cleaning equipment. In addition, the gun seat and the discharge valve are packaged, convenient to use.

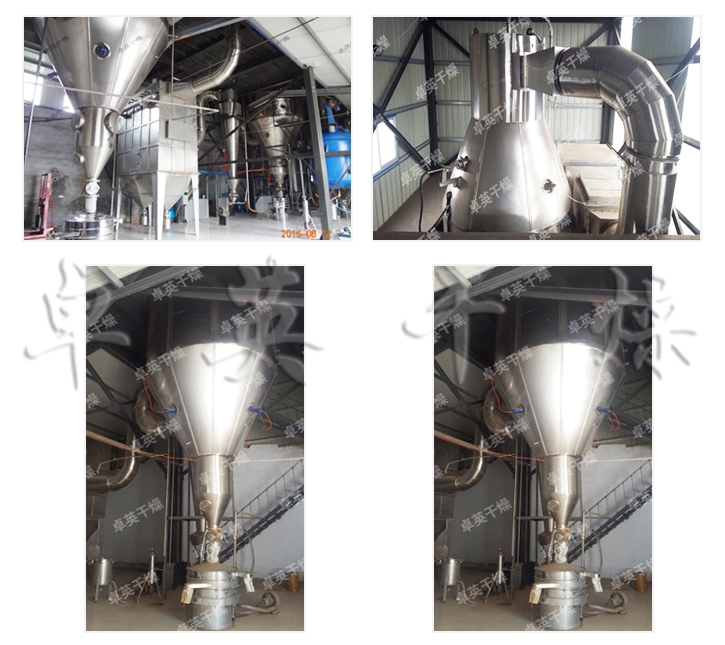

user site pictures

|

DF product big picture

typical users

For more details or requests for information, please contact us: CEO:Mr Chao 013912338885 |